Discover how implementing CAD design can significantly improve production efficiency for small businesses.

Understanding the Importance of CAD Design in Production

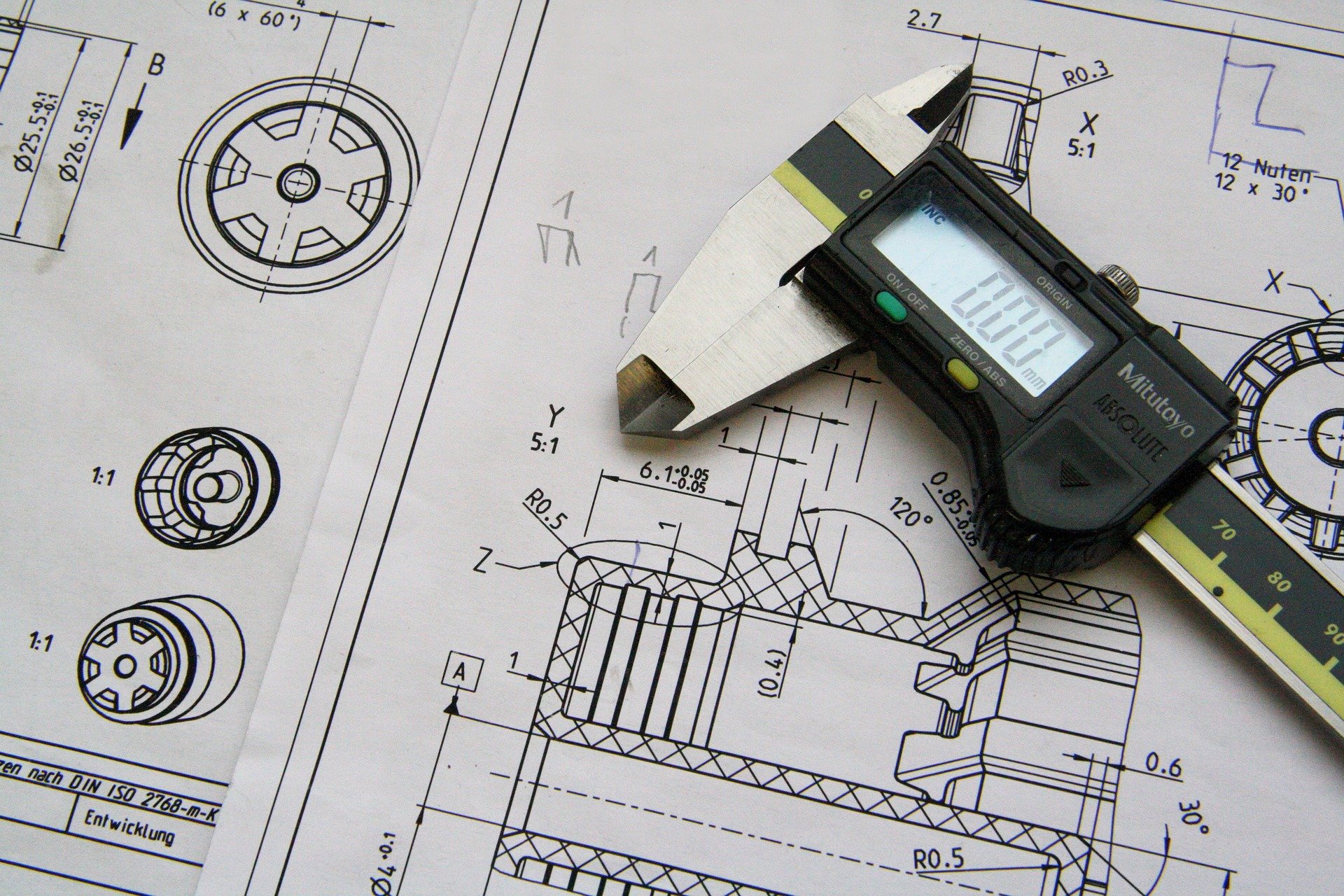

CAD design plays a crucial role in improving production efficiency for small businesses. With CAD (Computer-Aided Design), businesses can create digital models of their products or components, allowing for precise and accurate design representation. This enables manufacturers to visualize and simulate the production process, identify any potential issues or errors, and make necessary adjustments before moving into physical production. By using CAD design, small businesses can reduce the risk of costly errors and ensure the success of their production operations.

Additionally, CAD design enables businesses to streamline their design and production workflows. With traditional manual design methods, creating and modifying designs can be time-consuming and prone to errors. CAD software automates many design tasks, making it faster and more efficient to create, modify, and iterate on designs. This not only saves time but also allows businesses to respond quickly to design changes or customer demands. Overall, CAD design offers small businesses a powerful tool to optimize their production processes and achieve higher levels of efficiency.

Benefits of Implementing CAD Design in Small Businesses

Implementing CAD design in small businesses brings numerous benefits to their production operations. Firstly, CAD design improves design accuracy and precision. By creating digital models, businesses can ensure that their designs are dimensionally accurate and free from human errors. This leads to better quality products and reduces the need for rework or corrections during the production phase.

Secondly, CAD design enhances collaboration and communication among team members involved in the production process. With CAD software, designers, engineers, and other stakeholders can easily share and review design files, provide feedback, and make necessary changes. This fosters better teamwork, reduces miscommunication, and accelerates the design iteration process.

Furthermore, CAD design enables businesses to optimize material usage and reduce waste. By digitally simulating the production process, businesses can identify areas where material usage can be optimized, avoiding unnecessary waste and reducing production costs. This not only benefits the bottom line but also contributes to more sustainable and environmentally friendly production practices.

Lastly, CAD design allows businesses to create realistic visualizations and prototypes of their products. This helps in marketing and sales efforts, as businesses can showcase their designs to potential customers, investors, or stakeholders. By presenting a realistic representation of their products, businesses can generate interest, gather feedback, and secure orders more effectively.

Key Considerations for Implementing CAD Design

Before implementing CAD design in small businesses, it is important to consider certain key factors. Firstly, businesses need to invest in suitable CAD software that meets their specific design requirements. There are various CAD software options available in the market, each with its own features and capabilities. It is crucial to choose a software that aligns with the business's design needs, budget, and compatibility with existing systems.

Secondly, businesses should ensure that their employees receive proper training and support in using the CAD software. CAD design requires specific skills and knowledge, and providing training to employees can help them utilize the software to its full potential. This may involve conducting workshops, hiring external trainers, or utilizing online learning resources.

Additionally, businesses must consider the hardware requirements for CAD design. CAD software often requires powerful computers or workstations to run smoothly, so it is important to assess the business's current hardware infrastructure and make necessary upgrades if needed.

Lastly, businesses should develop a clear implementation plan for integrating CAD design into their production processes. This may involve setting specific goals, establishing timelines, assigning responsibilities, and conducting regular evaluations to track progress and make adjustments as necessary.

Best Practices for Integrating CAD Design into Production Processes

To successfully integrate CAD design into production processes, small businesses can follow some best practices. Firstly, it is important to involve all relevant stakeholders, such as designers, engineers, and production managers, in the design process. This ensures that different perspectives and expertise are considered, leading to better design outcomes.

Secondly, businesses should establish clear communication channels and guidelines for sharing design files and collaborating on design projects. This can include using cloud-based platforms for file sharing, implementing version control systems, and defining roles and responsibilities for each team member.

Furthermore, businesses should regularly update and maintain their CAD software to ensure compatibility and access to the latest features and enhancements. This may involve subscribing to software maintenance plans or regularly checking for updates from the software provider.

Moreover, businesses should encourage a culture of continuous learning and improvement in CAD design. This can involve organizing regular training sessions, promoting knowledge sharing among team members, and staying updated with industry trends and advancements in CAD technology.

Lastly, businesses should regularly evaluate the impact of CAD design on production efficiency and make necessary adjustments. This can involve analyzing production data, gathering feedback from employees, and identifying areas for further optimization or improvement.

Case Studies: How Small Businesses Achieved Production Efficiency with CAD Design

Several small businesses have successfully implemented CAD design to improve their production efficiency. One such example is a furniture manufacturer that used CAD software to create 3D models of their furniture designs. By simulating the production process in the CAD software, they were able to identify design flaws, optimize material usage, and reduce production time. This resulted in higher quality furniture products and improved customer satisfaction.

Another case study involves a small electronics company that implemented CAD design to streamline their product development process. By using CAD software, they were able to quickly iterate on designs, incorporate customer feedback, and reduce time-to-market for their products. This gave them a competitive edge in the market and increased their business growth.

These case studies highlight the tangible benefits that small businesses can achieve by implementing CAD design in their production operations. By leveraging the power of CAD software, businesses can enhance their design accuracy, collaboration, material optimization, and overall production efficiency.